. A short 2-page article, 4 Tips to Optimize Your Food & Beverage Production highlights some ways to drive food & beverage production performance improvements.

clean in place

Modernizing Clean in Place Operations

Emerson’s Marcus Parsons highlighted food & beverage manufacturers who modernize their CIP processes. They can significantly reduce cleaning time and consumption of expensive resources, resulting in less waste and more product.

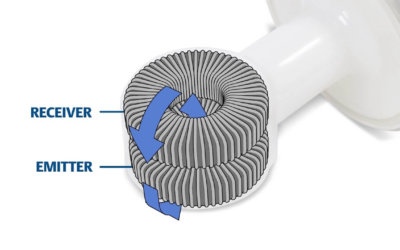

Conductivity Measurement for Optimized Clean-in-Place Operations

Common in the Life Sciences and Food & Beverage industries are clean-in-place (CIP) operations to effectively clean the interior surfaces of production process piping, vessels and other inline assets before the next batch is run. This short, 2:10 YouTube video,...

Applying the ISA88 Model to Clean In Place Operations

Every industry has its special jargon that is like a secret handshake. If you're an insider, you can quickly spot the outsiders based upon their understanding of your industry's jargon and acronyms. For instance, my background was in the offshore oil and gas business...

Keep Up to Date With the Latest News and Updates

Follow Us

We invite you to follow us on Facebook, LinkedIn, Twitter and YouTube to stay up to date on the latest news, events and innovations that will help you face and solve your toughest challenges.

Do you want to reuse or translate content?

Just post a link to the entry and send us a quick note so we can share your work. Thank you very much.

Our Global Community

Emerson Exchange 365

The opinions expressed here are the personal opinions of the authors. Content published here is not read or approved by Emerson before it is posted and does not necessarily represent the views and opinions of Emerson.