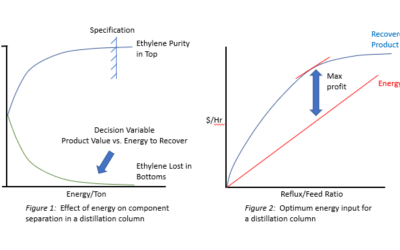

The cold section of an ethylene plant is responsible for cooling and purifying the product-grade ethylene, propylene and other bi-products from the cracking furnaces. Cracked gas is cooled in transfer-line exchangers which produce steam from the effluent gas energy. Gas is further cooled with water in the quench column, scrubbed and dried before being compressed in the cracked gas compressor and fed to the cold box.

value improvement practice

Driving Improved Pump Performance

Pumps do the heavy lifting of moving liquids through the production process. They consume more energy more than most types of plant assets and are subject to quite a bit of wear and tear. Online continuous monitoring enables operational performance improvements in...

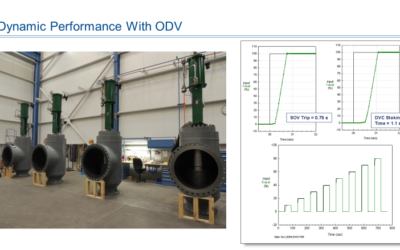

Compressor Anti-Surge Control Value Improvement Practice

An ethylene plant has a number of very large, very critical compressors which will cause the entire plant to shutdown if they ever trip. The cracked gas compressor increases the entire cold-side feed from around 3 psig to ~475 psig, typically through 5 stages. The two refrigeration compressors are the next biggest compressors that can also shut down the entire plant if they trip.

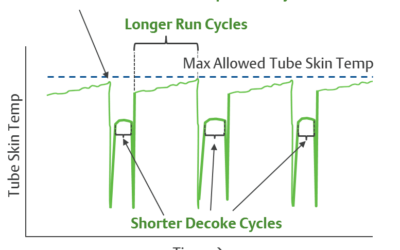

Ethylene Furnace Automation, Control & Optimization

Cracking furnaces are one of the most crucial parts of an ethylene complex. They set the production and yield for the entire plant. For furnace-limited plants, when a furnace is down, whether for maintenance or decoking, production is lost.

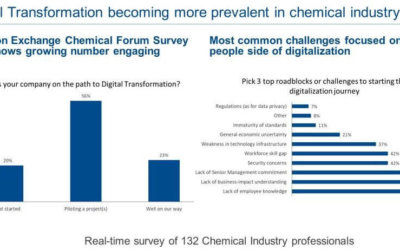

Digital Transformation and Top Quartile Performance for Petrochemical Producers

Digital Transformation is a buzz word that seems to be on everyone’s mind and lips these days. Most companies have one or more digitalization initiatives underway as demonstrated in this survey conducted at the 2019 Emerson Exchange during the Chemical Industry Forum session.

Keep Up to Date With the Latest News and Updates

Follow Us

We invite you to follow us on Facebook, LinkedIn, Twitter and YouTube to stay up to date on the latest news, events and innovations that will help you face and solve your toughest challenges.

Do you want to reuse or translate content?

Just post a link to the entry and send us a quick note so we can share your work. Thank you very much.

Our Global Community

Emerson Exchange 365

The opinions expressed here are the personal opinions of the authors. Content published here is not read or approved by Emerson before it is posted and does not necessarily represent the views and opinions of Emerson.