In an earlier post, Five Strategies for Mitigating Automation Project Risk, we highlighted the importance of prototyping:

Risks in budget, schedule, changes, and project execution can be reduced with a prototyping strategy. Prototyping helps incorporate operational philosophies into the upfront engineering, helps ensure consistent look and feel, and provides a visual medium to communicate designs to the project team, manufacturing, maintenance, and other interested parties. The prototype lays the foundation for the project guidelines and demonstrates methods for software testing, operator training, and process simulation. This strategy can reduce changes later in the project.

I caught up with Emerson’s Michalle Adkins who leads the Life Sciences consulting team. You may recall Michalle from earlier Life Science and operations management-related posts.

I caught up with Emerson’s Michalle Adkins who leads the Life Sciences consulting team. You may recall Michalle from earlier Life Science and operations management-related posts.

Michalle and the consultants work with many pharmaceutical and biotech manufacturers to improve and streamline operations. Using the Syncade Suite operations management software, she notes that prototyping plays a large role in these projects.

Prototyping has been a helpful tool for a lot of automation- and IT-type projects. In fact, in the Syncade world, prototyping is an even more significant and worthwhile tool for delivering a successful project.

One of the key benefits of prototyping is that it brings stakeholders together, and provides something to visualize—stimulating discussions, raising areas of concern, and helping people understand others’ perspectives. It’s critical to explore and manage culture change issues during this process.

Syncade solutions are used to manage different business processes that span functional organizational units. These business processes must be adjusted to include the elements and workflow that manufacturing execution system (MES) solutions provide.

For example, approval of master batch records will look a little different in the integrated electronic world and equipment logbooks and associated processes will be managed via the integrated solution versus paper and standard operating procedures (SOPs).

A prototype is one way to review the future state process with all of the stakeholders in order to gain alignment on how the business will be operated post project. Involving stakeholders during the prototyping phase helps to mitigate roll out risks.

Often manufacturers want to minimize customization and use off-the-shelf products to accomplish as much as possible. In so doing, these manufacturers need to evaluate how some of their business processes may need to change in order to stay aligned with this vision for the project.

Michalle cautions that it is critical to understand the capabilities and limitations of a potential solution–often one imagines what an MES should do and often even how it should do it. Regardless of the solution that you use, these requirements need to be vetted with all the stakeholders and compared to the capabilities of the MES solution.

There are often several different ways to accomplish the same task and one way may make more sense for one stakeholder while another way may make more sense for another stakeholder. The ideas generated from these discussions help to flesh out the ultimate requirements for an appropriately balanced solution.

The prototype does not need to be a completely developed solution and the review session can include slides of what the ultimate solution may include or contain. This session that includes a combination of an actual prototype and presentations is a useful tool for having conversations around critical processes while showing something tangible.

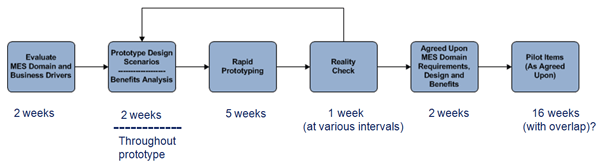

The prototypes contain agreed upon requirements, a basis of design for a pilot project, a starting library for similar objects that have been piloted, and a clear vision of what the solution will be. Here’s a sample prototype and pilot schedule:

Just as a picture is worth a thousand words, so a prototype is worth a hundred-page user requirements document.

You can share questions and ideas with the Life Sciences team over in the Life Sciences track of the Emerson Exchange 365 community.