One of the key ways to improve operational performance is to reduce unplanned downtime. An ARC Advisory Group blog post, Technology Trends to Watch for in 2017, noted: One of the biggest end user challenges remains unscheduled downtime. IIoT-enabled solutions, such as...

PeakVue

Avoiding Rotating Machinery Downtime with PeakVue Diagnostics

We all appreciate the diagnostics in our cars that provide early warning to get a problem fixed before a breakdown occurs. We've chronicled how rotating machinery diagnostics, such as PeakVue Analysis diagnostics, can provide early warning to avoid unplanned...

Multi-parameter Condition Monitoring for Plant Asset Reliability

Across many process manufacturing and producing industries, falling prices are driving the need for increased efficiency and reliability, as well as reduced costs. While optimizing process control can yield gains, so can applying technology to the condition of the...

Early Detection of Impending Pump Failures

Even non-critical pumps in your process can cause spills, vapor clouds, fires and worse. Most of these failure incidents provide warning well in time to solve the problem—if feedback mechanisms are in place for your operators and maintenance personnel. In tce, the...

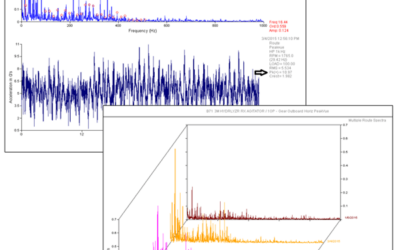

Detecting and Analyzing Mass Speed, Force, and Impact

When performing vibration measurements during route-based maintenance activities, different vibration measurements uncover different issues with plant machinery. In this 4:20 YouTube video, PeakVue Analysis, Emerson's Mark Granger demonstrates some of these...

Detecting and Analyzing Impact Energy on Rotating Equipment

Let's end this very busy week with a video which may be of interest if reliability and the management of plant assets falls within your set of responsibilities. In this 3:45 YouTube video, Impact Analysis with PeakVue and Autocorrelation, Emerson's Mark Granger...

What is Damaging Your Plant Machinery?

"Why do some machines fail early, while others operate for many additional years?" Emerson's Ray Garvey and Spectro's Pat Henning open with this great question in a Machinery Lubrication article, Identifying Root Causes of Machinery Damage with Condition Monitoring....

Rotating Equipment Bearings and Potholes

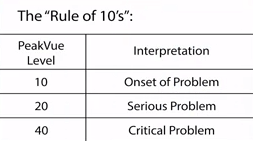

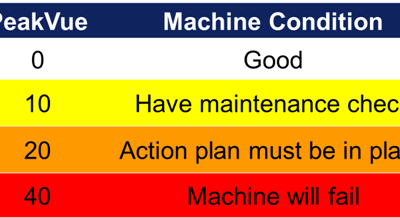

Concerning yesterday's post, Avoiding Bearing Failures with the Rule of Tens PeakVue Measurement Methodology, I received an email with a great analogy about pits in ball bearings and potholes. Driving your car on a freshly paved circular track is like a PeakVue...

Avoiding Bearing Failures with the Rule of Tens PeakVue Measurement Methodology

Few things wreck a good day at the plant, mill, platform, wellpad, or other process like a bearing failure on an important pump, compressor, fan, or other piece of rotating machinery. Identifying the problem early before it leads to an unplanned shutdown means the...

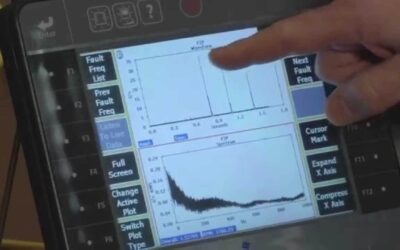

Mobile Device Task-Based Procedures for Vibration Analyzers

The growing impact of smart phones and tablet technology continue to impact our everyday lives, including our world of process automation. I heard from some friends on Emerson's Machinery Health Management team of a new mobile site, the CSI 2140 Mobile Procedure. It...

Portable Vibration Analyzer-Human Centered Design Style

You may have seen the news of a next generation of portable vibration analyzer, the CSI 2140 Machinery Health Analyzer. Portable vibration analyzers are great for providing advance warning of machinery failures as part of a predictive maintenance program. The CSI 2140...

How Technology Can Help Miners Improve Brownfield Operations

As miners face many economic and technical headwinds, Emerson's Douglas Morris of the metals and mining and power industry teams, describes how technology can improve mine productivity by reducing unplanned downtime. If you've picked up the newspaper recently, you've...

Keep Up to Date With the Latest News and Updates

Follow Us

We invite you to follow us on Facebook, LinkedIn, Twitter and YouTube to stay up to date on the latest news, events and innovations that will help you face and solve your toughest challenges.

Do you want to reuse or translate content?

Just post a link to the entry and send us a quick note so we can share your work. Thank you very much.

Our Global Community

Emerson Exchange 365

The opinions expressed here are the personal opinions of the authors. Content published here is not read or approved by Emerson before it is posted and does not necessarily represent the views and opinions of Emerson.